Choosing the Right Optical Fibre Diameter Analyser for Your Fibre Optic Manufacturing Needs

Exactly How an Optical Fibre Diameter Analyser Improves Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser right into Fibre production procedures stands for a considerable innovation in quality control methods. By offering real-time, exact dimensions of Fibre sizes, this innovation resolves the crucial requirement for uniformity in manufacturing requirements.

Significance of Fibre Diameter Measurement

Precise measurement of Fibre Diameter is important in the area of optical Fibre innovation, as it straight affects the efficiency and reliability of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capability, depletion, and total transmission efficiency. Accuracy in gauging Fibre Diameter guarantees that the optical buildings are maintained within specified tolerances, which is vital for ideal signal stability.

Variants in Fibre Diameter can bring about enhanced losses due to spreading and modal diffusion, impacting the high quality of information transmission. In high-speed communication systems, such disparities can lead to considerable deterioration of signal high quality, causing information mistakes and lowered efficiency. Furthermore, consistent Fibre Diameter is crucial for compatibility with connectors and splicing technologies, which are indispensable components of Fibre optic networks.

Quality assurance processes in Fibre production greatly count on accurate Diameter measurements to ensure conformity with industry criteria. By carrying out robust dimension methods, manufacturers can improve product integrity, reduce waste, and improve general system performance. Therefore, the importance of Fibre Diameter dimension can not be overstated, as it offers as a foundation in the improvement of optical Fibre modern technology and its applications in modern interaction networks.

How the Analyser Functions

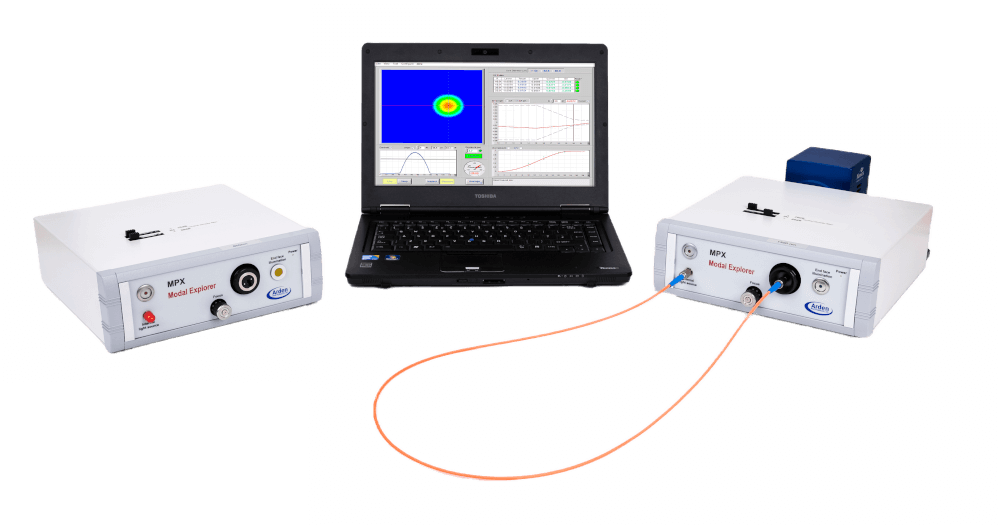

The effective dimension of Fibre Diameter counts on advanced logical methods that ensure precision and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a combination of laser modern technology and progressed image processing formulas to accurately evaluate the Diameter of fibres as they are created

At first, a laser beam is routed at the relocating Fibre, developing a cross-sectional darkness. The analyser captures this shadow making use of high-resolution video cameras positioned purposefully along the assembly line. The captured pictures are after that refined in real-time to determine the Fibre's Diameter with exceptional accuracy.

The system uses innovative formulas that make up various elements, including variations in light intensity and ecological problems, to boost dimension integrity. It can detect minute changes in Diameter, such as changes that may happen throughout the production procedure.

Furthermore, the analyser is qualified of managing several fibers simultaneously, enhancing throughput without jeopardizing accuracy. By offering instant comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial role in maintaining stringent quality assurance criteria, ensuring that the end product satisfies sector specs and client requirements.

Advantages of Real-Time Surveillance

While typical approaches of checking Fibre Diameter typically include time-consuming post-production checks, real-time surveillance significantly enhances the performance and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive approach permits makers to determine deviations in Fibre Diameter as they happen, as opposed to waiting until manufacturing is total to assess top quality

By continually gauging the Diameter during production, suppliers can make sure that the fibres meet rigid specs, resulting in lowered variability and boosted consistency. Real-time surveillance likewise enables prompt restorative activities to be taken, reducing waste and preventing malfunctioning fibers from going into the supply chain.

Furthermore, this modern technology assists in enhanced data collection and evaluation, supplying understandings into manufacturing trends and prospective locations for enhancement. Such data-driven decision-making encourages producers to maximize procedures and preserve high requirements of quality control.

Additionally, real-time surveillance fosters a culture of continual improvement within the manufacturing environment. Workers are a lot more involved when they can see the effect of their operate in real-time, causing enhanced liability and a dedication to excellence. On the whole, the implementation of real-time monitoring systems in optical Fibre manufacturing equates to premium item quality and increased customer contentment.

Influence On Manufacturing Performance

Applying optical Fibre Diameter analysers dramatically boosts manufacturing performance by simplifying the production procedure. These tools assist in constant tracking of Fibre Diameter, allowing manufacturers to spot discrepancies in real-time. By determining disparities quickly, assembly line can be changed rapidly, decreasing downtime and lowering the probability of creating defective products.

In addition, the assimilation of these visit this site analysers into the production workflow makes it possible for far better resource allocation. With accurate Diameter measurements, drivers can maximize product use, making certain that sources are not squandered on mistaken fibers. This precision additionally adds to less junk and remodel, ultimately decreasing production prices.

The automation supplied by optical Fibre Diameter analysers reduces dependence on manual examinations, which are usually lengthy and prone to human error. Consequently, employees can concentrate on more strategic tasks, enhancing general productivity.

Additionally, the data produced from these analysers can inform process renovations and assist in far better decision-making. By examining trends in Fibre Diameter variations, makers can implement aggressive measures to boost production strategies and maintain regular quality. In summary, optical Fibre Diameter analysers play a vital role in increasing manufacturing efficiency, resulting in greater quality output and boosted profitability.

Situation Researches and Success Stories

Across different markets, case studies highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One prominent example is a leading telecoms firm that encountered challenges with inconsistent Fibre diameters, causing boosted denial rates. By integrating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre measurements, causing a 30% decrease in defects and considerable price financial savings.

Furthermore, a study organization concentrating on sophisticated materials used optical Fibre Diameter analysers to refine their speculative processes. The analyser's capacity to supply detailed understandings into Fibre consistency allowed the development of cutting-edge materials with enhanced performance attributes.

These success stories emphasize the necessary function of optical Fibre Diameter analysers in boosting quality control, boosting production performance, and driving development throughout diverse markets.

Verdict

To conclude, the Optical Fibre Diameter Analyser plays an essential role in improving quality control within Fibre manufacturing. By providing exact, real-time measurements and assisting in immediate restorative activities, this modern technology considerably minimizes irregularity and reduces waste. The application of such innovative tools promotes a society of continual improvement and operational effectiveness, inevitably making certain compliance with industry requirements and preserving competition. As demonstrated through different situation researches, the analyser proves vital for attaining premium product quality in Fibre manufacturing.

The application of optical Fibre Diameter analysers permitted for strict quality control, making certain that the created fibers fulfilled exacting sector standards.In verdict, the Optical Fibre Diameter Analyser plays a pivotal function in enhancing quality control within Fibre manufacturing.